PRODUCTS

LEGACY

Ethos of Late Seth Gordhan Das Rathi as to high standards quality integrity, honesty, and inclusives prosperity are pursued by the Group. They setup a small Re-Rolling Mill in Delhi in the early 40’s. Since then, the Group has grown continuously. The Group owes its presence in the steel industry to the farsightedness of Late Seth Gordhan Das Rathi and his two younger brothers and nephew.

MAJOR MILESTONES

Started

1942

1st Steel Re-rolling mill commissioned at Loni Road, Shahdara, Delhi.

1947

Won Exclsuive right to use TOR on the steel bars in North India from Tor Istag Steel Corporation, Luxemberg.

1953

1st to start production of TOR STEEL in India

1965

Birth of brand RATHI

1970

North India 1st Mini Steel Plant commissioned

1990

Introduction of branded retailing of Steel bars through the concept of Exclusive RATHI TOR steel shops

2003

Commissioning of M/s. Shri Rathi Steel Limited, Ghaziabad

2005

Introduction of TMT bars in North India.

2007

Won rights from CENTRE DE RECHERCHES METALLURGIQUES, BELGIUM to use TEMPCORE on the steel bars.

2007

Commissioning of M/s. Shri Rathi Steel Dakshin Limited, Bhiwadi

2009

Launch of brand "EUROTHERM"

2011

Launch of Mera Steel - Indias 1st Made to Order RATHI steel bars.

2014

Launch of EUROTHERM Binding Wire.

2015

Launch of EUROTHERM 7 STAR.

2015

Launch of EUROTHERM Rings

2017

Launch of 7STAR 600 Grade TMT Bar.

2018

Launch of 7STAR Made to Order TMT Bar.

2020

Launch of 7Star 550D/500D Grade TMT Bar.

2021

Increase in monthly capacity by 80%.

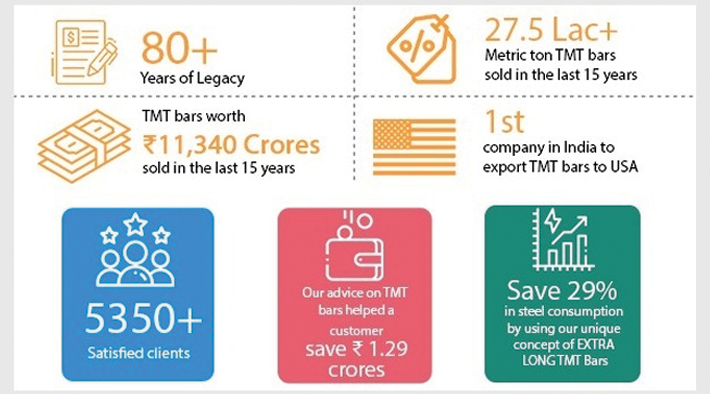

WHY CHOOSE US

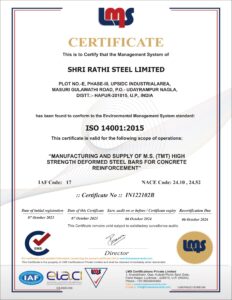

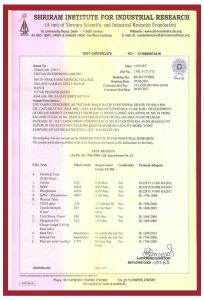

- One of the most renowned and trusted bearer of the 80 YRS OLD

RATHI STEEL LEGACY. - ACCREDITED BY GLOBAL CERTIFICATIONS like ISO 9001, ISO 14001 and

ISO 18001 - CERTIFIED BY BUREAU OF INDIAN STANDARDS (BIS) to manufacture

Steel Re-bars as per IS:1786/1985 - AVAILABLE IN 600, 550D, 500D, 500 and CRS grades, thereby fulfilling the needs of

every customer - TECHNICAL ASSISTANCE FROM HEEP&P (Human Engineering for Environmental Products and Production), Germany

- One of the few manufacturers in India who are AUTHORISED TO USE THE PRESTIGIOUS TEMPCORE BRAND NAME.

- We use one of the WORLD’S MOST RENOWNED TMT PROCESS TECHNOLOGY, “TEMPCORE” from the CRM (centre De Recherches Metallurgiques) group

of Belgium. TATA Steel and Steel Authority of India Limited also use TEMPCORE technology to manufacture their TMT bars - State of the art COMPUTER CONTROLLED PRODUCTION PROCESS MONITORS each 7 STAR TMT bars on a millisecond basis, thereby guarantying CONSISTENT QUALITY

- 7 STAR TMT bars by RATHI can HELP YOU SAVE UPTO 20% IN STEEL CONSUMPTION as compared to the ordinary Fe-415 grade TMT bars

- AVAILABLE IN CUSTOMISED LENGTHS OF UPTO 29 METERS eliminating wastage due to scrap generation and also avoiding overlapping in case of long spans

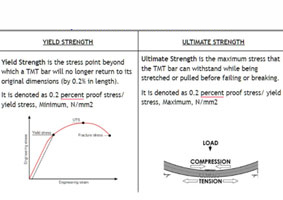

4 FACTS AND SECRETS RELATING TO TMT BARS!

Hidden secret: DUE TO INCORRECT BENDING PRACTICE of TMT bars adopted at the site, contractors PREFER SOFTER TMT BARS, which are often lower in strength.

A recent incident REVEALED 12% THEFT OF TMT BARS by the transporter. Do you want to save yourself from such incidents?

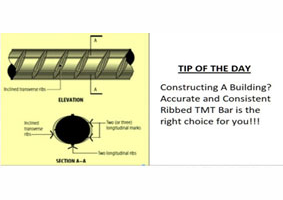

Constructing a building? Facts reveal that an ACCURATE AND CONSISTENT RIBBED TMT BAR is the right choice for you!!!

OUR CLIENTS

WHAT OUR CUSTOMERS SAY ABOUT US!

“I have personally seen the production of

7 STAR TMT steel bars and I was most

impressed with their quality consciousness.

From the row material to the finished

product...”

Pawan Gupta

Director (Procurement) - Gaursons Promoters Pvt. Ltd.

“I have found that 7 STAR TMT bars give

us perfect elongation combined with the

highest tensile strength.

The greatest benefit for us is lower steel

consumption leoding to substantial cost

saving.”

Prashant Jain

Director - Sarla Holdings Pvt. Ltd.

“7 STAR is the only company that could

give us bars that are 18 meters in straight

length.

This eliminated overlapping and we could

achieve huge saving in costs”

Rajender Bhandari

Director - Bestech Group