Study reveals:- Consistent Tensile Strength is important for an ideal TMT bars

For any construction project, essential features of the material being used are: sturdy and long-lasting.

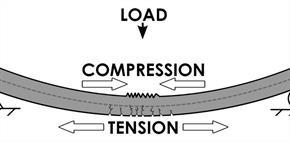

In the entire construction process, TMT bars are considered to be the most important material, as they make the structure, strong and long-lasting TMT Bars not only offer the building enough load-bearing capacity, but also gives it strength to withstand deadly earthquakes.

In this paper, we will explain ‘Tensile Strength’ in simple words and why it is amongst the most crucial factors in constructing a strong and long-lasting building.

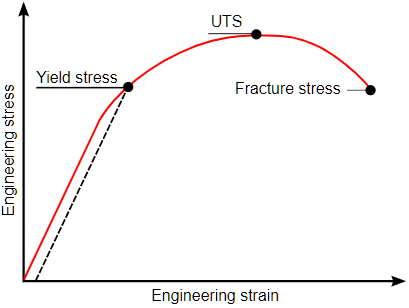

Tensile strength is a measurement of the force required to pull a TMT bar to the point where it breaks. There are two typical definitions of tensile strength:

YIELD STRENGTH

ULTIMATE STRENGTH

Yield Strength is the stress point beyond which a TMT bar will no longer return to its original dimensions (by 0.2% in length).

It is denoted as 0.2 percent proof stress/ yield stress, Minimum, N/mm2

Ultimate Strength is the maximum stress that the TMT bar can withstand while being stretched or pulled before failing or breaking.

It is denoted as 0.2 percent proof stress/ yield stress, Maximum, N/mm2

Impact of Yield Strength and Ultimate Strength on the strength of the building

- Higher Yield Strength may cause premature failure of beam in an undesirable failure mode, such as brittle shear failure instead of more ductile and desirable flexure mode.

- Lower Yield Strength, as is usually observed in the case of nonstandard TMT bars, will reduce the margin of safety and increase risk of premature failure.

- Strict control on Ultimate Strength value of TMT bars is also a must. Very high Ultimate Strength can change the behaviour of the reinforcement steel to undesirably and make it very brittle.

Conclusion

Tensile Strength is a parameter of the Maximum Load (Ultimate Strength) and Minimum Load (Yield Strength) which the TMT bar can take when load is applied on it. The Tensile Strength in TMT bars should be consistent in nature as both lower and higher Tensile Strength are a threat to the TMT bar during adverse stress conditions like in the case of an Earthquake. The Bureau of Indian Standards (BIS) has also specified the Tensile Strength for various grades of TMT bars and the same is available by clicking on this link:- https://bit.ly/3huHay5

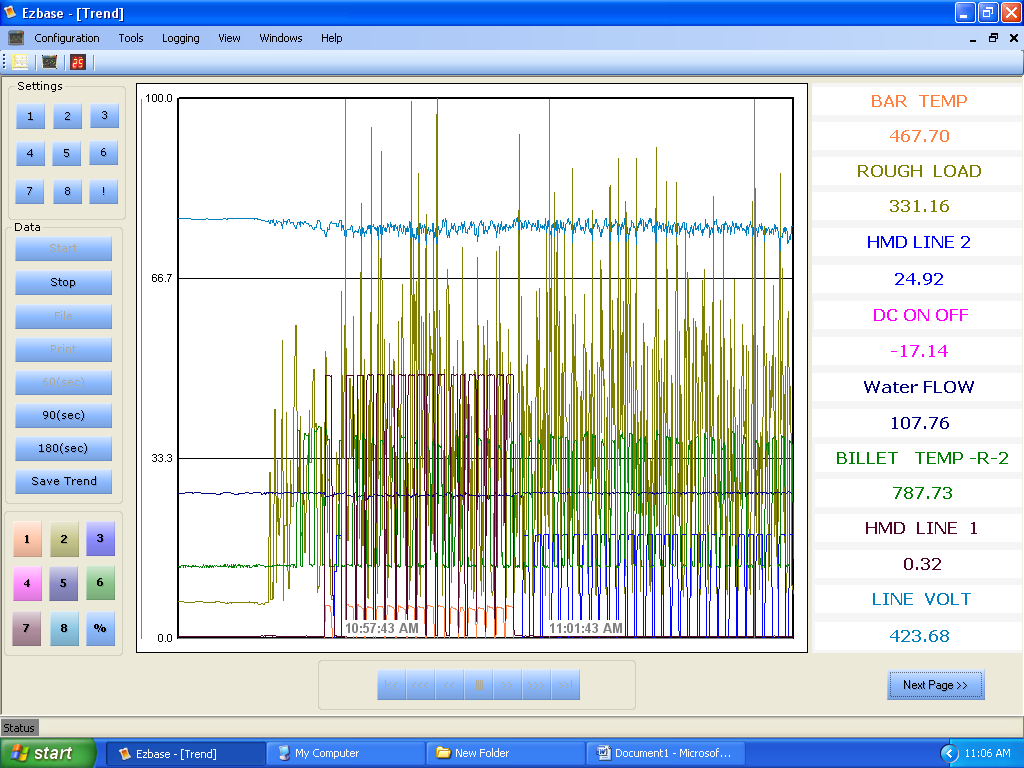

The Computer Controlled production process at 7 STAR TMT bars ensures that each TMT bar is continuously monitored during production on a millisecond level, thereby resulting in not even the slightest variation in the values of Yield Strength and Ultimate Strength.